DIN338 Potpuno brušena HSS M2 spiralna svrdla

Značajke

DIN338 potpuno brušeno spiralno svrdlo HSS M2 ima nekoliko izvanrednih značajki, uključujući:

Materijal od brzoreznog čelika (HSS) M2: Korištenje HSS M2 materijala pruža vrhunsku tvrdoću, otpornost na habanje i otpornost na toplinu, što ove svrdla čini prikladnima za bušenje raznih materijala, uključujući nehrđajući čelik, legirani čelik i nemetalne materijale, crni metal.

POTPUNO BRUŠENI ŽLJEBOVI I REZNI RUBOVI: Svrdlo je precizno brušeno kako bi se osigurali oštri i konzistentni utori i rezni rubovi, što rezultira poboljšanim odvodom strugotine, smanjenim trenjem i povećanom točnošću bušenja.

Razdvojeni vrh od 135 stupnjeva: Svrdlo ima dizajn razdvojenog vrha od 135 stupnjeva, što pomaže smanjiti potrebu za pilotnim rupama, poboljšava mogućnosti centriranja i samocentriranja te poboljšava učinkovitost bušenja.

SJAJNA ZAVRŠNA OBRADA: Sjajna završna obrada svrdla otporna je na koroziju, potiče protok strugotine i pruža poboljšanu vidljivost tijekom rada, što pomaže u poboljšanju performansi i vijeka trajanja.

Usklađenost s DIN338: Bušilice su u skladu s DIN338 standardima, osiguravajući dosljedne dimenzije, visokokvalitetnu izradu i zadovoljavajući industrijske standarde za točnost i pouzdanost.

Svestrana primjena: Ova spiralna svrdla prikladna su za opće zadatke bušenja u raznim materijalima, što ih čini svestranim i praktičnima za razne primjene bušenja.

Dugi vijek trajanja alata: Kombinacija visokokvalitetnih HSS M2 materijala, preciznog brušenja i izdržljivog dizajna pomaže produžiti vijek trajanja alata i smanjiti učestalost zamjene i održavanja.

Zajedno, ove značajke čine DIN338 potpuno brušeno HSS M2 spiralno svrdlo pouzdanim, visokoučinkovitim alatom za profesionalne i industrijske primjene bušenja.

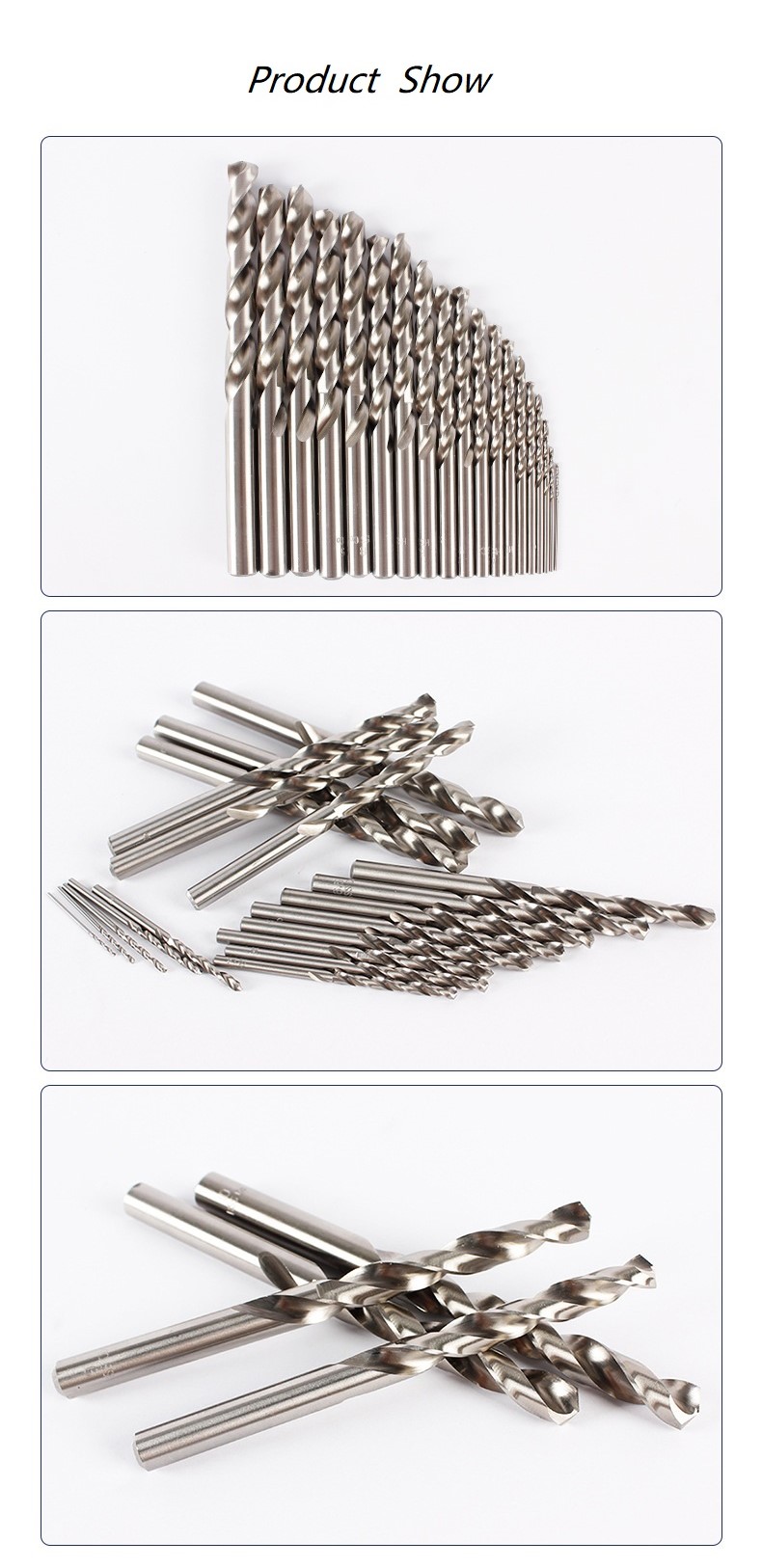

PROIZVOD show

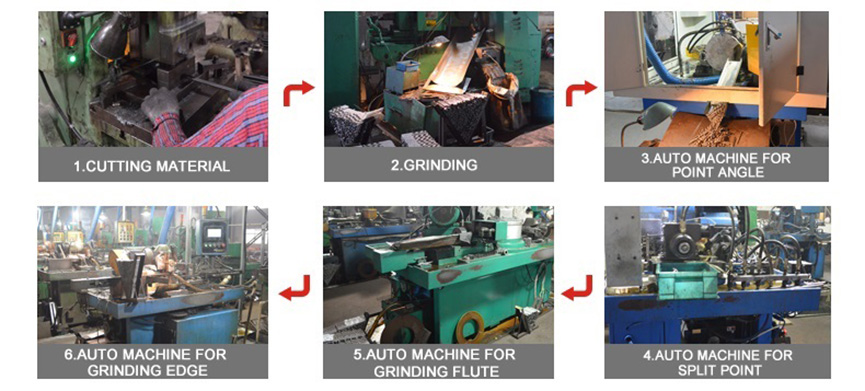

TIJEK PROCESA

Prednosti

DIN338 potpuno brušena HSS M2 spiralna svrdla nude niz prednosti, uključujući:

Visoka izdržljivost: HSS M2 materijal pruža vrhunsku tvrdoću i otpornost na habanje za dugotrajnu izdržljivost, posebno pri bušenju kroz tvrde materijale poput nehrđajućeg čelika, legiranog čelika i obojenih metala.

Preciznost i točnost: Potpuno brušeni žljebovi i rezni rubovi osiguravaju precizne i dosljedne performanse bušenja, stvarajući čiste i točne rupe.

Učinkovito odvođenje strugotine: Precizno brušeni žljebovi i rezne ivice omogućuju učinkovito odvođenje strugotine, smanjujući začepljenje i povećavajući učinkovitost bušenja.

Povećana brzina bušenja: Dizajn s podijeljenim vrhom od 135 stupnjeva smanjuje potrebu za prethodnim bušenjem, omogućujući brže bušenje i povećanu produktivnost.

SMANJUJE TOPLINU I TRENJE: Materijal od brzoreznog čelika i precizno brušenje pomažu u smanjenju nakupljanja topline i trenja tijekom bušenja, što rezultira glatkijim radom i duljim vijekom trajanja alata.

Otpornost na koroziju: Svijetla površina svrdla otporna je na koroziju, što produžuje vijek trajanja svrdla i održava njegove performanse rezanja. Svestranost: Ova svrdla prikladna su za razne primjene bušenja, što ih čini svestranim i praktičnima za upotrebu u raznim materijalima i industrijama.

Pružajući ove prednosti, DIN338 potpuno brušeno spiralno svrdlo HSS M2 pruža pouzdanost, učinkovitost i dugotrajnost u operacijama bušenja.

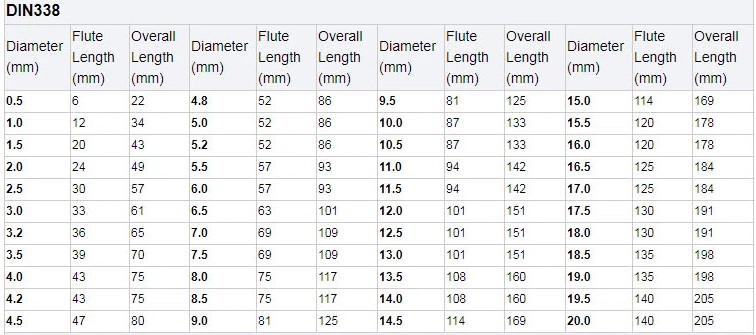

| DIN338 HSS SPIRALNA SVRDLA | ||||||||

| Promjer (mm) | Duljina flaute (mm) | Ukupna duljina (mm) | Promjer (mm) | Duljina flaute (mm) | Ukupna duljina (mm) | Promjer (mm) | Duljina flaute (mm) | Ukupna duljina (mm) |

| 0,2 | 2,5 | 19,0 | 5.6 | 57,0 | 93,0 | 11,0 | 94,0 | 142,0 |

| 0,3 | 3.0 | 19,0 | 5.7 | 57,0 | 93,0 | 11.1 | 94,0 | 142,0 |

| 0,4 | 5.0 | 20,0 | 5.8 | 57,0 | 93,0 | 11.2 | 94,0 | 142,0 |

| 0,5 | 6.0 | 22,0 | 5.9 | 57,0 | 93,0 | 11.3 | 94,0 | 142,0 |

| 0,6 | 7.0 | 24,0 | 6.0 | 57,0 | 93,0 | 11.4 | 94,0 | 142,0 |

| 0,7 | 9,0 | 28,0 | 6.1 | 63,0 | 101,0 | 11,5 | 94,0 | 142,0 |

| 0,8 | 10,0 | 30,0 | 6.2 | 63,0 | 101,0 | 11.6 | 94,0 | 142,0 |

| 0,9 | 11,0 | 32,0 | 6.3 | 63,0 | 101,0 | 11,7 | 94,0 | 142,0 |

| 1.0 | 12,0 | 34,0 | 6.4 | 63,0 | 101,0 | 11,8 | 94,0 | 142,0 |

| 1.1 | 14,0 | 36,0 | 6,5 | 63,0 | 101,0 | 11,9 | 101,0 | 151,0 |

| 1.2 | 16,0 | 38,0 | 6.6 | 63,0 | 101,0 | 12,0 | 101,0 | 151,0 |

| 1.3 | 16,0 | 38,0 | 6,7 | 63,0 | 101,0 | 12.1 | 101,0 | 151,0 |

| 1.4 | 18,0 | 40,0 | 6,8 | 69,0 | 109,0 | 12.2 | 101,0 | 151,0 |

| 1,5 | 18,0 | 40,0 | 6,9 | 69,0 | 109,0 | 12.3 | 101,0 | 151,0 |

| 1.6 | 20,0 | 43,0 | 7.0 | 69,0 | 109,0 | 12.4 | 101,0 | 151,0 |

| 1,7 | 20,0 | 43,0 | 7.1 | 69,0 | 109,0 | 12,5 | 101,0 | 151,0 |

| 1,8 | 22,0 | 46,0 | 7.2 | 69,0 | 109,0 | 12.6 | 101,0 | 151,0 |

| 1,9 | 22,0 | 46,0 | 7.3 | 69,0 | 109,0 | 12,7 | 101,0 | 151,0 |

| 2.0 | 24,0 | 49,0 | 7.4 | 69,0 | 109,0 | 12,8 | 101,0 | 151,0 |

| 2.1 | 24,0 | 49,0 | 7,5 | 69,0 | 109,0 | 12,9 | 101,0 | 151,0 |

| 2.2 | 27,0 | 53,0 | 7.6 | 75,0 | 117,0 | 13,0 | 101,0 | 151,0 |

| 2.3 | 27,0 | 53,0 | 7,7 | 75,0 | 117,0 | 13.1 | 101,0 | 151,0 |

| 2.4 | 30,0 | 57,0 | 7,8 | 75,0 | 117,0 | 13.2 | 101,0 | 151,0 |

| 2,5 | 30,0 | 57,0 | 7,9 | 75,0 | 117,0 | 13.3 | 108,0 | 160,0 |

| 2.6 | 30,0 | 57,0 | 8,0 | 75,0 | 117,0 | 13.4 | 108,0 | 160,0 |

| 2.7 | 33,0 | 61,0 | 8.1 | 75,0 | 117,0 | 13,5 | 108,0 | 160,0 |

| 2,8 | 33,0 | 61,0 | 8.2 | 75,0 | 117,0 | 13,6 | 108,0 | 160,0 |

| 2.9 | 33,0 | 61,0 | 8.3 | 75,0 | 117,0 | 13,7 | 108,0 | 160,0 |

| 3.0 | 33,0 | 61,0 | 8.4 | 75,0 | 117,0 | 13,8 | 108,0 | 160,0 |

| 3.1 | 36,0 | 65,0 | 8,5 | 75,0 | 117,0 | 13,9 | 108,0 | 160,0 |

| 3.2 | 36,0 | 65,0 | 8.6 | 81,0 | 125,0 | 14,0 | 108,0 | 160,0 |

| 3.3 | 36,0 | 65,0 | 8,7 | 81,0 | 125,0 | 14.3 | 114,0 | 169,0 |

| 3.4 | 39,0 | 70,0 | 8,8 | 81,0 | 125,0 | 14,5 | 114,0 | 169,0 |

| 3,5 | 39,0 | 70,0 | 8,9 | 81,0 | 125,0 | 14,8 | 114,0 | 169,0 |

| 3.6 | 39,0 | 70,0 | 9,0 | 81,0 | 125,0 | 15,0 | 114,0 | 169,0 |

| 3.7 | 39,0 | 70,0 | 9.1 | 81,0 | 125,0 | 15.3 | 120,0 | 178,0 |

| 3.8 | 43,0 | 75,0 | 9.2 | 81,0 | 125,0 | 15,5 | 120,0 | 178,0 |

| 3.9 | 43,0 | 75,0 | 9.3 | 81,0 | 125,0 | 15,8 | 120,0 | 178,0 |

| 4.0 | 43,0 | 75,0 | 9.4 | 81,0 | 125,0 | 16,0 | 120,0 | 178,0 |

| 4.1 | 43,0 | 75,0 | 9,5 | 81,0 | 125,0 | 16.3 | 125,0 | 184,0 |

| 4.2 | 43,0 | 75,0 | 9.6 | 87,0 | 133,0 | 16,5 | 125,0 | 184,0 |

| 4.3 | 47,0 | 80,0 | 9,7 | 87,0 | 133,0 | 16,8 | 125,0 | 184,0 |

| 4.4 | 47,0 | 80,0 | 9,8 | 87,0 | 133,0 | 17,0 | 125,0 | 184,0 |

| 4,5 | 47,0 | 80,0 | 9,9 | 87,0 | 133,0 | 17.3 | 130,0 | 191,0 |

| 4.6 | 47,0 | 80,0 | 10,0 | 87,0 | 133,0 | 17,5 | 130,0 | 191,0 |

| 4.7 | 47,0 | 80,0 | 10.1 | 87,0 | 133,0 | 17,8 | 130,0 | 191,0 |

| 4,8 | 52,0 | 86,0 | 10.2 | 87,0 | 133,0 | 18,0 | 130,0 | 191,0 |

| 4.9 | 52,0 | 86,0 | 10.3 | 87,0 | 133,0 | 18,5 | 135,0 | 198,0 |

| 5.0 | 52,0 | 86,0 | 10.4 | 87,0 | 133,0 | 18,8 | 135,0 | 198,0 |

| 5.1 | 52,0 | 86,0 | 10,5 | 87,0 | 133,0 | 19,0 | 135,0 | 198,0 |

| 5.2 | 52,0 | 86,0 | 10.6 | 87,0 | 133,0 | 19.3 | 140,0 | 205,0 |

| 5.3 | 52,0 | 86,0 | 10,7 | 94,0 | 142,0 | 19,5 | 140,0 | 205,0 |

| 5.4 | 57,0 | 93,0 | 10,8 | 94,0 | 142,0 | 19,8 | 140,0 | 205,0 |

| 5,5 | 57,0 | 93,0 | 10,9 | 94,0 | 142,0 | 20,0 | 140,0 | 205,0 |